Unbelievable results of 3D printing in Health Sector

3D Printing has proven to be one of the most disruptive technology in recent times, its disruption have cut across many sectors ranging from engineering, transportation, agriculture and so on. That notwithstanding, in the area of health and medicine, we could all say that its impact is being felt more hence its potential to change medicine and healthcare in the nearest future.

While the focus has been on 3D printing implants and medical devices used by patients, one of the largest areas of application is the fabrication of anatomical replicas. Doctors are currently utilizing models produced by 3D printing from patient scan data to enhance the diagnosis of illnesses, clarify treatment decisions, plan, and, in some cases, even practice chosen surgical interventions in advance of the actual treatments.

The models enable doctors to understand patient anatomy that is difficult to visualize, especially when using minimally invasive techniques. Models also assist in precisely sizing medical devices. Doctors can also utilize the models to explain an upcoming medical procedure to patients and their families and to communicate the surgical steps to their colleagues.

To help reduce cost, some facilities have developed procedures where surgeons practice and plan operations on cheap mannequins that are transplanted with patient-specific 3D printed models. Surgeons can now obtain an even better understanding of precisely how a procedure needs to be performed right down to the touch and feel of the distinctive parts of a patient’s anatomy. FDM printers are perfect for geometrically basic surgical models that don’t require a high level of detail or include intricate features.

3D printing in medicine is part of the innovative process called additive manufacturing, which means producing three-dimensional solid objects from a digital file. How the technology works, we explained the technology in our article on bio-printing here.

As technology evolves, researchers work on various solutions. For example, engineers from the University of Buffalo have created a novel technology speeding up the printing process itself. What’s remarkable about this particular hydrogen-based technology is that it’s way faster than previous 3D printing methods. Like, up to 50 times faster.

3D printing in medicine and healthcare could revolutionize drug creation and the production of medical equipment. It could also offer new methods for practicing medicine, optimizing supply chains, and propose cheaper and way more personalized medical services.

Some of the uses of 3D printing in Healthcare today

The applications of 3D printing in healthcare today outweigh what have been imagined some of which include:

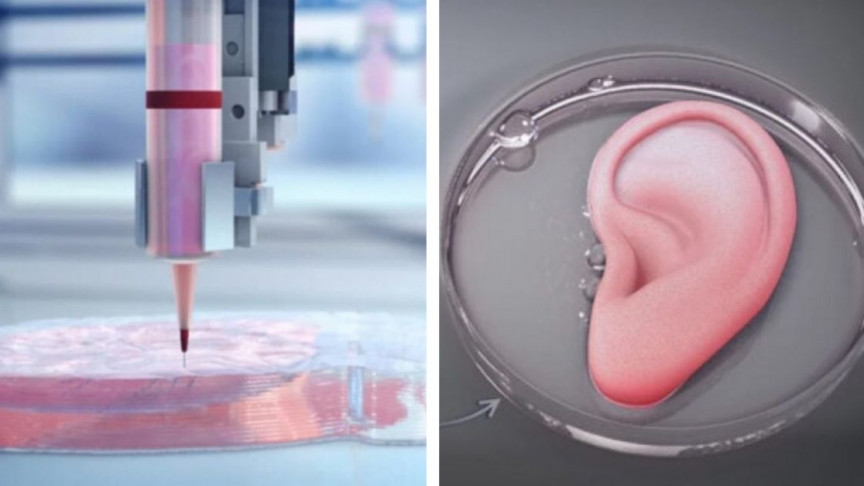

Use of 3D Printing in regenerative medicine

There is a major health crisis in terms of the shortage of organs, as the population is living for longer due to medical advances. Since 2013, the number of patients requiring an organ has doubled, while the actual number of available donor organs has barely moved (HRSA, 2020).

Regenerative medicine involves many different areas, using scaffolds, biomaterials, cells, or a combination of biomaterials and cells to attempt to create organs for transplants instead of relying on the current donor model. Recently, the creation of multilayered objects (tissues/organs) from soft biomaterials such as living cells and biomimetic synthetic polymers has been the most challenging technological advancement in the field.

Although many problems need to be solved for complex organs (such as the heart or liver) to be 3D bio-printed and subsequently transplanted into a patient, simple organs such as the bladder have been transplanted into patients since the early 2000s.

Use of 3D in Personalised medical equipment

It is a well-known fact that medical equipment is expensive. Total spending on medical devices in the U.S. reached about $200 billion in 2018. Thus, 3D printing splints, medical models used before surgeries or other necessary means for healing could save vast amounts of money. And there are already brilliant examples on the market of how to do it!

Ian McHale, a senior at the US Steinert High School, created a blueprint for producing finger splints. A low-end 3D printer can print his splint quickly and affordably, about 2¢ worth of ABS plastic in about ten minutes! For developing countries, where splints can often be ordered from overseas only in bulk, it could mean the cheapest solution for poor communities. At the same time, it could efficiently serve personal needs.

As for 3D printed plaster casts, for the moment, these remain a distant hope. In theory, it sounds amazing; however, the technology still seems niche, facing several challenges before its mass adoption. We dedicated an entire article looking for the solutions and the companies providing them – find out more in Where Are 3D-Printed Casts? But 3D printing in medicine can also be a lifesaver – as it saved a life of a baby in the U.S. Kaiba Gionfriddo was born prematurely in 2011 and suffered from tracheobronchomalacia – a congenital disability that causes the windpipe to collapse. He had a tracheotomy and was put on a ventilator––the conventional treatment. Still, Kaiba would stop breathing almost daily. His heart would stop, too. His caregivers 3D printed a bioresorbable device that instantly helped Kaiba breathe. After the operation, Kaiba’s trachea has gradually reconstructed itself. His body reabsorbed the inserted splint. A year later, the tube was also removed without causing any harm.

Australian scientists 3D printed a set of micro-needles for effective diabetes monitoring. These minimally invasive and minimally painful needles offer an effective way for continuous glucose monitoring – and opens up the path towards personalized medicine and drug intake itself.

Use of 3D Printing in personalized/precision medicine

3D printing offers a completely new opportunity for the development and preparation of personalized medicines at both the pharmacy and industrial scale. Introducing 3D printers to pharmacies and hospitals would allow physicians, nurses, and pharmacists to form a dose and delivery system based on the patient’s body size, age, lifestyle, and sex. This would make medicine personal to the patient, and also save money and resources.

Aprecia Pharmaceuticals is the only company with an approved 3D printed pharmaceutical, Spritam for the treatment of epilepsy.

Streamlined and more efficient R&D processes

There is a growing R&D crisis occurring in the pharmaceutical industry, as drugs are failing at later and later stages. Bio-printed tissues and organs are already being used to help increase the success rate of clinical trials. With bio-printing, researchers can print fully functional organs made of human cells to test a drug’s efficacy prior to using in vivo animal or human tests. This not only reduces the damage caused to animals, but also expedites the entire R&D process.

Accessibility

Pharmaceutical R&D and production is expensive. In many Western countries, the cost is supplemented in some way by the government, but in other areas worldwide, particularly poverty-stricken countries, there is simply no viable way for these patients to afford treatment. Additive manufacturing promises to bridge that divide. 3D printing is already being implemented to produce pharmaceuticals by the US company Aprecia.

Prosthetics have historically been expensive. Certain organizations have been designing prosthetics that can be 3D printed from commercially available, affordable desktop printers.

Diagnosis and medical training

3D printing of models affords further insights into pathological changes, as well as a visualization of patient-specific organ anatomy. The education and surgical planning fields are two of the heaviest investors in 3D printing for the healthcare industry.

Leveraging additive manufacturing as a pre-operative planning tool has shown extremely promising results. The influx of organs required for transplant, particularly livers and kidneys, together with the scarcity of cadavers is increasing the need to use organs from healthy donors.

Models for surgical planning and education

3D printing can also help medical research and the outcome of complex operations and particularly challenging cases. Researchers in China and the US have both 3D printed models of cancerous tumors to aid the discovery of new anti-cancer drugs and to better understand how tumors develop, grow, and spread. Bio-printed cancer models can even “mimic the 3D heterogeneity of real tumors.

Researchers have also used scans of animal hearts to create printed models and then added flexible electronics on top of those models. The material can be peeled off the printed model and wrapped around the real heart for a perfect fit. The next step is to enhance the electronics with multiple sensors.

3D printing in medicine can be used to print organ models. These could also be helpful for patient education and pre-operative planning for surgeons. Just recently, scientists are using a combination of MRI and ultrasound imaging along with 3D-printing technology to help doctors prepare for fetal surgeries. With the 3D printed model, doctors can more easily identify potential obstacles and reduce the risk of surgery on babies with spina bifida, a congenital disability.

Another example is Schiner 3D Repro GmbH Digital Anatomy 3D printer. The device can help simulate anatomies and pathologies with ultra-realistic 3D printed models, reducing the need for human and animal cadavers, ensuring high repeatability and acceleration across the design validation process.

Prosthetics and implants

Globally, over 30 million people need mobility devices such as prosthetics, while 80 percent of the world’s amputees do not have access to modern prosthetics. However, creating traditional prosthetics is very time–consuming and destructive, which means that any modifications would destroy the original moulds. In collaboration with Autodesk Research and CBM Canada, researchers at the University of Toronto used 3D printing to quickly produce cheap and easily customisable prosthetic sockets for patients in the developing world.

NGOs like Refugee Open Ware and Not Impossible are also helping people in need with 3D printing in medicine. They create 3D-print prosthetics for refugees from war-torn areas. Not Impossible, for example, took 3D printers to Sudan, where the chaos of war has left many people with amputated limbs. The organization’s founder, Mick Ebeling, trained locals to operate the machinery, create patient-specific limbs, and fit these new, very inexpensive prosthetics.

Personalized medical implants could also be 3D printed. This is especially important in complex and rare cases. Back in 2014, Dutch surgeons replaced the entire top of a 22 year–old woman’s skull with a customized printed implant made from plastic. The patient was suffering from a rare condition that caused the inside of her skull to grow extra bone, which squeezed her brain. The growth was discovered after she reported severe headaches and then lost her sight and motor control. If untreated, the extra bone would have killed her.

A novel 3D printing technique makes it possible to create astonishingly small and complex biomedical implants. Engineers and biomedical scientists at RMIT University in Australia created a ‘reverse’ 3D printing, versatile enough to use medical grade materials off-the-shelf. “The approach involves printing glue moulds that can then be filled with biomaterial filler. Once the mould is dissolved away, the biomaterial structure remains. Excitingly, the technique uses standard 3D printers, such as those now commonly even found in high schools, and PVA glue as a printing material.” Imagine the possibilities of this achievement!

Despite these numerous advantages of 3D in healthcare and medical sector, there are fears as to issues like:

Product liability risk

With 3D printing, pharmaceutical companies can authorise their blueprints to pharmacies and healthcare providers. Thus, they can now easily print drugs locally.

However, pharmaceutical companies cannot possibly oversee the efficiency of every 3D printing operation. Moreover, they need to consider the potential product liability implications.

According to the pharmaceutical companies’ role in providing their product blueprint, they may be partially responsible for any undesirable incidents or product defect claims.

Other parties involved such as the printer manufacturer, material supplier, software designer, and product manufacturer may also be liable for this fallout.

For pharmaceutical companies who are planning to venture into 3D printing, they should develop a policy for certifying their blueprints. In this way, they will ensure that they are financially and legally protected.

Cyber risk

The rapid increase in reproducing fake pills is one of the greatest concerns with 3D printing. Furthermore, 3D printers are now being used by hackers to produce counterfeit medicines faster than the traditional manufacturing method.

As an illustration, hackers who gain access to a medicine’s blueprint can mass-produce the drug overseas. This can exploit the intellectual property of the pharmaceutical company. Moreover, if the drug is improperly produced, it can cause harm to the patients. Thus, hitting the pharmaceutical company’s reputation and financial status.

Apart from that, hackers can also make modifications to the medicine’s ingredients or doses. This may lead to severe health consequences for the patients.

IN CONCLUSION

3D printing has been an advanced technology in the field of medicine. It has the potential to open new doors in product development, manufacturing and product distribution. Aside from that, it allows the personalization of medicine to be more accessible.

Apart from the benefits that are mentioned above, the downsides of 3D printing in this industry must also be considered. Nonetheless, for pharmaceutical companies who are considering 3D printing in the future, understanding the drawbacks that are listed above must be the priority.

Feel free to live a comment below

There are no comments for now. Be the first comment